Applications of Ion Exchange Resin

Ion exchange resins are multipurpose materials that make it easier to remove or exchange specific ions from solutions. They are used in a wide range of applications including Domestic, Commercial and Industrial Process such as Chemical Industries, Water purification, Pharmaceutical applications where these resins are essential for separating materials, purifying liquid and ensuring efficient functioning of various Industrial process.

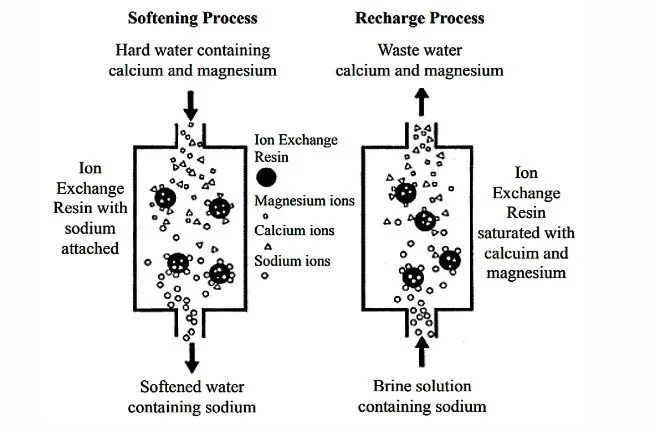

Water Softening :

The ion exchange method softens water by replacing calcium and magnesium ions with sodium ions. This enhances soap efficiency by reducing interference from calcium and magnesium ions, resulting in better lather and improved cleansing. Overall, ion exchange improves water quality and cleaning activities.

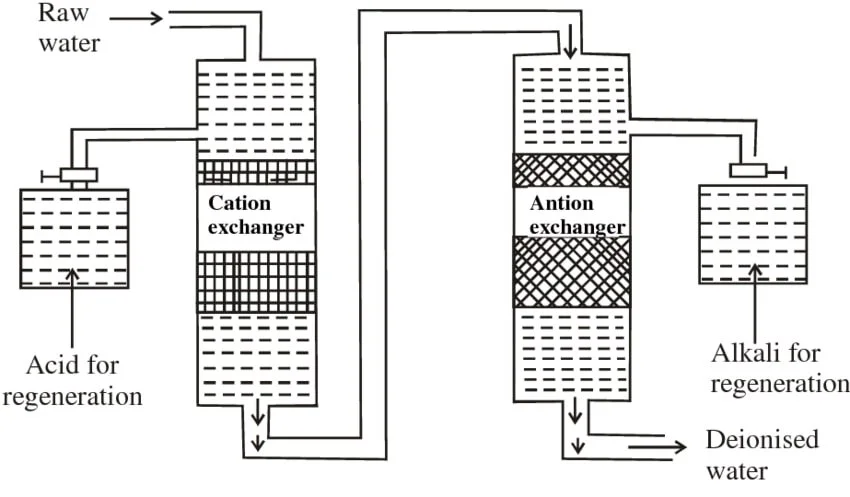

Water Demineralization :

The ion exchange method is employed for the removal of all minerals from water to achieve a high level of purity. In this process, the water is initially treated with cation resins in its hydrogen form to eliminate all cations present. Subsequently, the water passes through anion resins in the hydroxyl group, which removes all anions, including those from the resins. As a result, the newly introduced ions, H+ and OH-, combine to form water molecules. The resulting water contains minimal amounts of sodium and silica.

Demineralization Process

Water DE alkalization: De alkalization is a process that reduces the alkalinity in water. As a result, there is a decrease in both the hardness and the sodium content associated with alkalinity. Ultimately, these reductions lead to a decline in the concentration of dissolved minerals present in the water.

Special Ion Removal Applications: Specialty resins refer to a class of polymers that possess distinct properties and characteristics, making them well-suited for specific applications. These resins are created by modifying base polymers through chemical reactions or blending with other materials. They demonstrate exceptional thermal stability, impact resistance, chemical resistance, and superior mechanical properties, which contribute to their high desirability across various industries. Among the different types of specialty resins, chelating resins are particularly common and are utilized for selectively removing specific metals or ions like Iron, Arsenic, Fluoride, Barium, Strontium, etc. They are also employed in processes such as brine softening.

Nuclear Industry Applications:

Ion exchange resins play a vital role in the nuclear power generation industry, contributing to improved safety measures, enhanced efficiency, and effective waste management practices. These resins are utilized for various purposes, including the removal of radioactive isotopes, purification of water, nuclear fuel reprocessing, decontamination processes, and waste management procedures.

Boiler and Cooling water Treatment:

Industrial companies often require a boiler feed water treatment system to ensure efficient and high-quality steam generation. The presence of minerals and ions in boiler and cooling water can lead to scale formation, corrosion, and reduced performance, resulting in increased operational and maintenance costs. To prevent these issues, Ion exchange resins can be used to avoid plant downtime, expensive maintenance fees, and boiler failure. By addressing scaling, corrosion, and fouling, the system ensures optimal operation and longevity of the boiler and downstream equipment.

Heavy Metal Removal Application:

With industrial growth and human activities like plating, electroplating, battery production, and pesticide use, heavy metal levels in wastewater are increasing. These non-biodegradable and possibly cancer-causing substances endanger living beings and industries needing pure water.

Ultrapure Water Production Applications:

Ion exchange is crucial in the final polishing of ultrapure water for power and semiconductor industries. It removes ionic contaminants and meets specific purity requirements. Power industry tackles corrosion-causing impurities while semiconductor industry fights microbial and particle contaminants. As demand for ultrapure water rises, ion exchange is vital to meet quality standards.

Food & Beverage Industry Applications:

Ion exchange has many uses like removing trace elements, replacing substances, and isolating valuable components. It can also work as a catalyst. In the food industry, ion exchange is used for sugar production, dairy manufacturing, and water purification. It is also used in biochemistry and enzyme purification.

Pharmaceutical Industry:

Ion exchange resins are widely used in the pharmaceutical industry for various purposes, such as catalyzing reactions, isolating/purifying ingredients, and serving as excipients in formulations like tablets. They have multiple functions, including taste masking, drug release, tablet disintegration, improving bioavailability, and enhancing chemical stability.

Chemical Industry:

Ion exchange resins are important in the chemical industry for different processes like extracting heavy metals, improving surface quality, and coating. They are essential for making phenol, chlorine, and caustic soda.

Textile Industry:

Ion exchange resins find multiple uses in textile processes, serving various purposes such as water treatment, chemical recovery, effluent treatment, process water purification, desalination, detergent regeneration, and color fixation.

References:

1. https://en.wikipedia.org/wiki/Dealkalization_of_water

2. https://samcotech.com/different-types-ion-exchange-resins-applications-serve/

3. https://www.excedr.com/resources/ion-exchange-resins-what-they-are-and-their-applications

4. https://www.linkedin.com/pulse/ion-exchange-resins-nuclear-power-plants-ivey-guo

5. https://samcotech.com/what-is-a-boiler-feed-water-treatment-system-how-does-it-work/

Explore Doshion's industrial water treatment resins for process transformation. Visit Doshion's Industrial Water Treatment Resins page : https://www.doshionpoly.com/ion-exchange-resin