How Softeners Work

What is Hard Water?

As part of the Earth’s water cycle, when the water vapor precipitates and falls on the land as rain, it percolates down through various minerals and rocks to be collected as ground water. Since majority of earth’s crust consists of limestone, chalk, gypsum, and other similar miners which are largely made up of Calcium and Magnesium carbonates, bicarbonates, and sulphates, they get readily absorbed in the water. This type of water with dissolved calcium and magnesium ions as called Hard Water.

Need for Softening

Hard water can typically be indicated by lack of foaming and formation of scales in equipment that come in contact with water. In an Industrial setting, water hardness is very closely monitored as it can cause frequent breakdowns in boilers, cooling towers, etc. and cause frequent scaling and choking of pipes.

In an industrial setting, Soft water is essential as it can avoid major breakdowns, especially in high pressure boilers, where scaling can drastically reduce heat transfer efficiency and can be a cause of structural failure of the boiler.

In a domestic setting, many people opt for soft water due to avoid scales on sanitary fittings, and choking in pipes, which can sometimes require the entire pipeline to be replaced.

How does Water Softening Work?

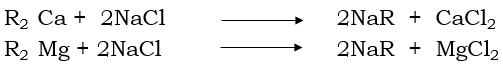

Across the world, the most common process for softening of hard water is by using Ion-Exchange Resin. Ion-Exchange Resin are polystyrene beads having special chemical layers which enable them to attract specific unwanted elements (ions) and exchange them with other wanted elements (ions).

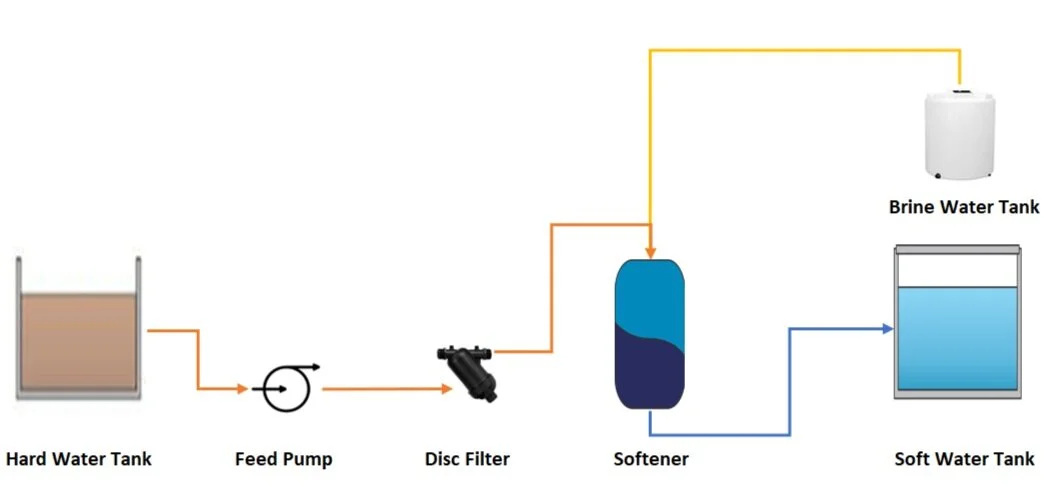

In a Water Softening Plant, a filter is filled with Ion – Exchange Resin (Strong Acid Cation Type). Ion-Exchange Resin are porous beads which let water and other liquids readily pass though. When water flows through these Resin beads, the calcium and magnesium ions in the water are replaced (exchanged) with Sodium Ions. Since water with high levels of hardness can easily rust metal, typically for softening applications, the filters are either of FRP or MSRL material.

Typical Process Flow Diagram

Softener Regeneration

All Resins have a specific exchange capacity corresponding to how much Calcium and Magnesium they can absorb and exchange with Sodium. Once that capacity is exhausted, these resins are required to be regenerated to regain the exchange capacity.

This regeneration process is done by flowing high saturated brine solution (Water with high quantity of dissolved salt-NaCl in it) through the resin. During this regeneration process, the resin beads reabsorb Sodium (Na) and release Calcium (Ca) and Magnesium (Mg) back into the water. The output water is very hard and contains TDS of approximately 40,000 – 50,000 ppm. This water needs to be disposed off correctly as per the local government regulations.

Important Characteristics when selecting Softening Resin:

Strong Acid Cation Resin

Type of Resin: For Softening Application, Strong Acid Cation resin are used since they have the best exchange characteristics which suite the required application

Exchange Capacity: Resins with higher Exchange Capacity give better performance of removing hardness. Exchange capacity of resin is measured in meq/L or mN. Typically, they lie between the range of 1.8 to 2.0 meq/L.

Ionic Form: Strong Acid Cation resin are available mainly in 2 ionic forms of Na+ and H+. For softening applications, resin with the ionic form of Na+ is used since the H+ ionic form can make the water very acidic when passed through.

Particle Size: Usually the Particle Size of Ion Exchange Resin used in softeners range from 0.3 - 1.2 mm However for industrial application, Uniform Particle Size (UPS) resin are also available which have a consistent particle size between 0.5 - 0.7 mm and thus provides better flow and less pressure drops over time.

Doshion’s Range of Water Softening Resin

Doshion has been manufacturing water softening resin for more than 45 years. Doshion has the following 4 main resins types used in water softening according to their different exchange capacities.